Modern press brake at FACO Metalltechnik

Current topic

New press brake from Safan Darley

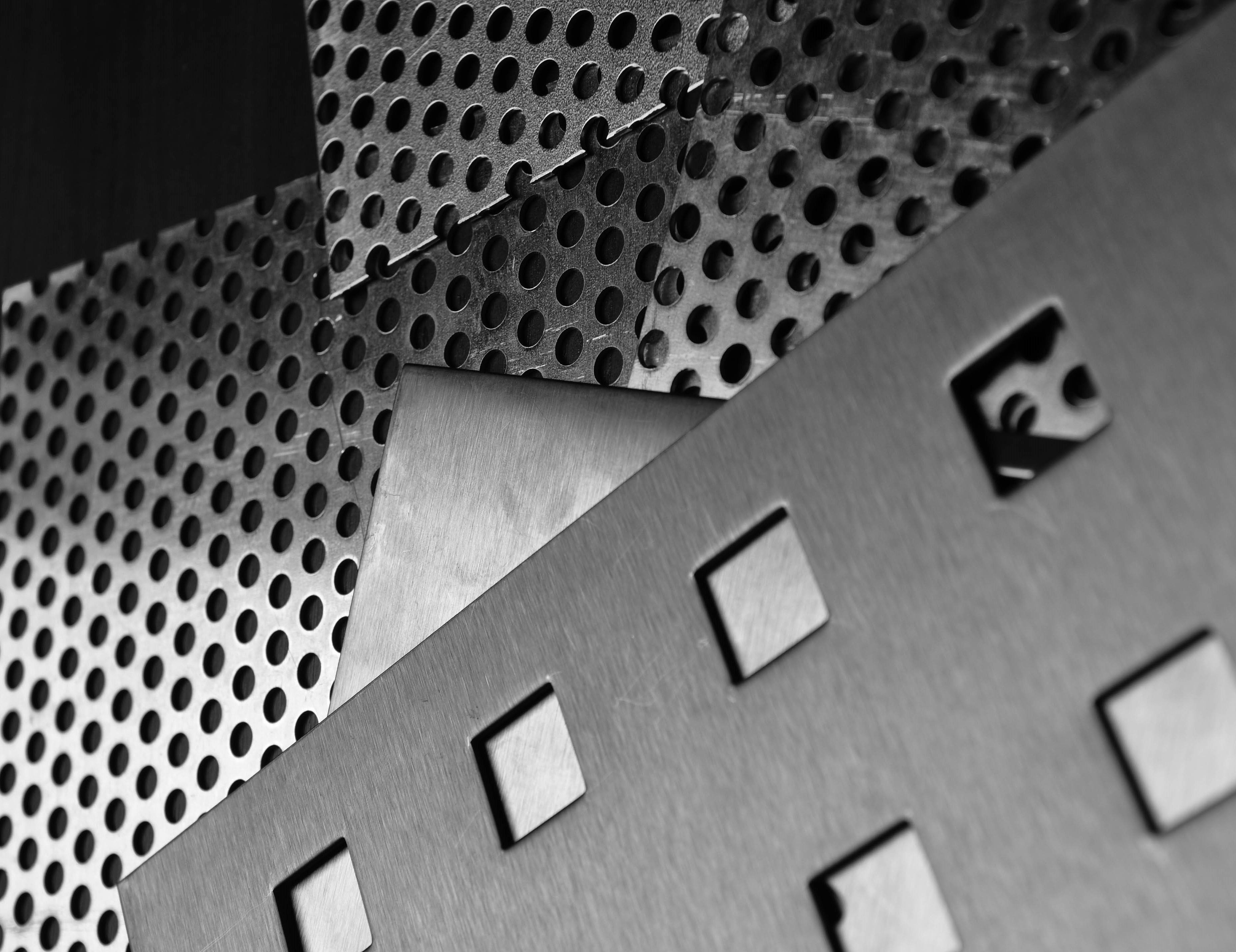

FACO Metalltechnik is once again setting a milestone in the continuous development of its production processes: the recent investment in a state-of-the-art press brake from Safan Darley opens up new horizons for the company's production portfolio. With this strategic expansion, FACO is emphasising its commitment to quality, efficiency and future-oriented technologies.

The production of precise metal components requires not only expertise, but also advanced technologies. At FACO Metalltechnik, we are breaking new ground here by making targeted use of the possibilities of digitalisation to optimise our production processes.

A key advantage of the new press brake is the intuitive programming in the office. The programs created are transferred to the machine, which saves time and minimises human error. On the machine display, the employee receives clear instructions on how to process the workpiece as well as step-by-step instructions. This makes the employee's qualifications less crucial, which is a significant advantage in times of a shortage of skilled labour.

Automation also extends to the selection and positioning of tools. The press brake independently determines the optimum tools for the task at hand and utilises them precisely. This smart function not only enables a significant reduction in set-up times, but also ensures extremely efficient production, even with small batch sizes.

The servo-hydraulic press brake has a pressing force of 1700 KN with a maximum working length of 3650 mm. The plan is to process sheets up to 3500 mm long in the thin and medium sheet range. All common materials from steel to aluminium and stainless steel will be processed. In a second step, a bending aid will be added this autumn to support the machine operator in lifting and guiding heavy sheets.

The investment in this innovative press brake marks a significant step towards digitalisation for FACO Metalltechnik. We consciously focus on technologies that not only strengthen our production capacities, but also help to minimise our environmental impact. For us, efficiency and sustainability go hand in hand.

The modern press brake is proof of our determination to take on the challenges of Industry 4.0 while providing our customers with high-quality products. We look forward to presenting you with even more innovative solutions from FACO Metalltechnik in the future. Stay tuned for further developments that reflect our passion for technology and metalworking.