Sustainable management

Sustainable management

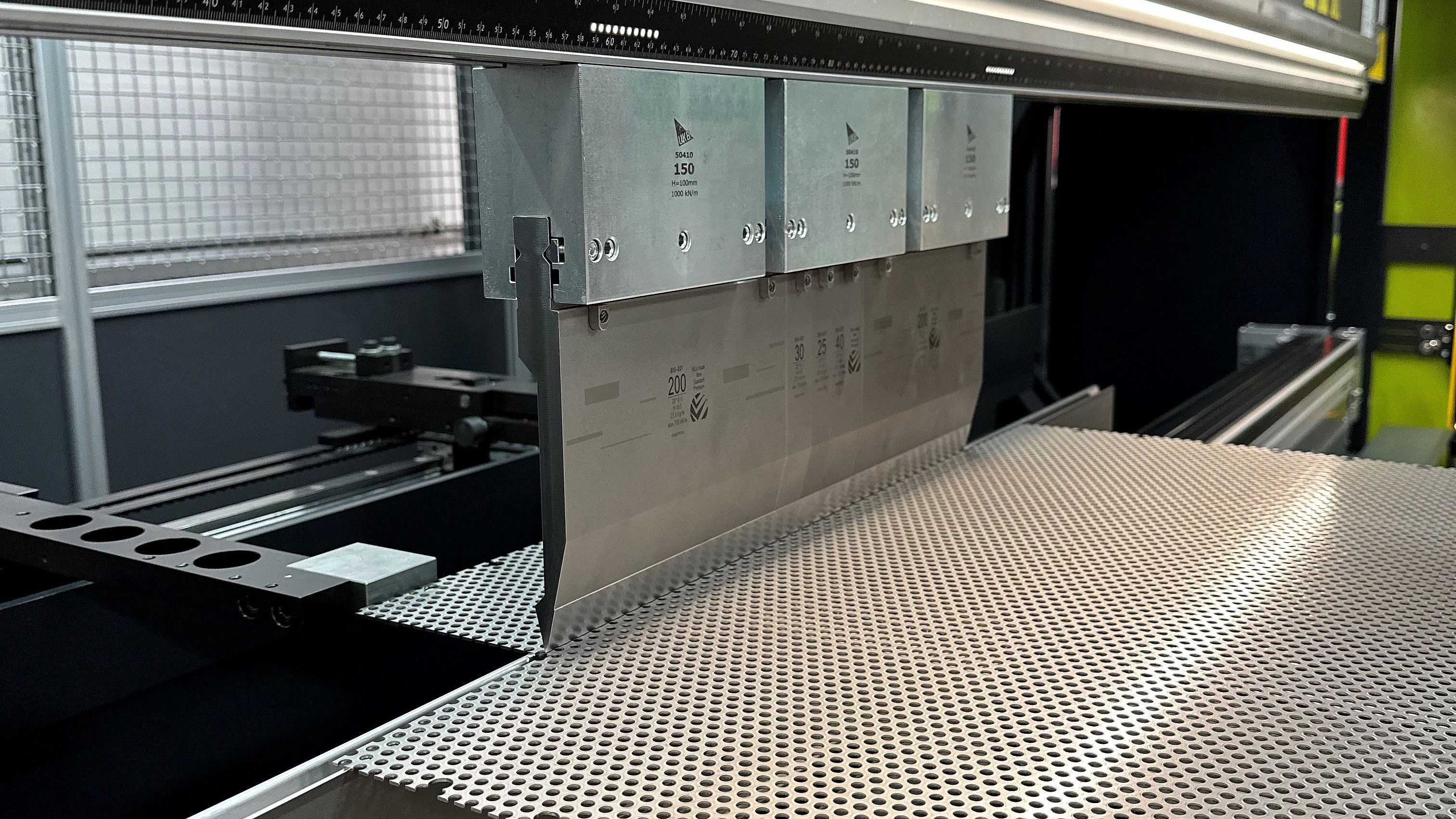

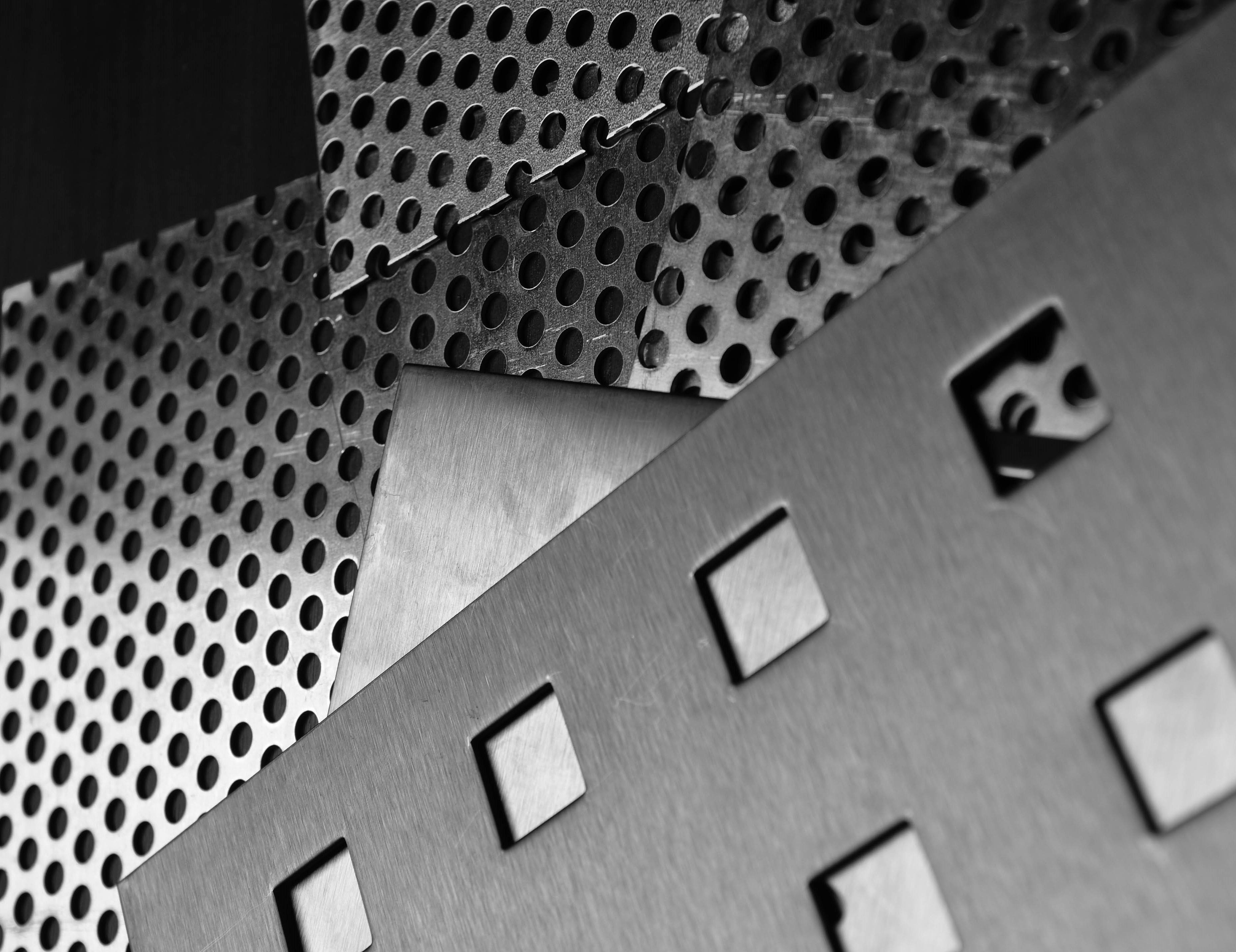

Metal industry and sustainability are not contradictory

Particularly in a sector in which metal is produced or processed, the issue of sustainable management is relevant because of the generally high energy consumption. It is not necessarily about the raw material itself, which in our case is basically recyclable. We at FACO have anchored the aspect of environmentally conscious action in our corporate guidelines at an early stage. Many examples show how this is reflected in strategic decisions and in everyday actions.

In the medium term, we are striving for a change to electric mobility for our field staff in the vicinity. By changing delivery logistics, we have been able to reduce loading and unloading times and the number of truck trips. This will make our personnel deployment more efficient and reduce emissions. A switch to digital invoicing initially seemed relatively simple. However, it soon became clear how interlocked and complicated a modified EDP system can be. Nonetheless, after completion of the project, the result was increased productivity in the administration department. As early as 2016, we successfully participated in the municipal ÖKOPROFIT project. We wanted to consolidate our knowledge of environmental issues and see if there are further adjustments. Operational environmental management and sustainable business management, as well as on-site consulting and exchange with other participants were the focus.

Some measures are costly, complex and expensive. But even less obvious habits or work or process adjustments can help to reduce resource consumption and cut costs. For us, economic thinking and environmental sustainability increasingly go hand in hand. Of course there are exceptions: Pallets made of cardboard have a better eco-balance compared to the wooden version. However, the use at our company showed that the load-bearing capacity was not sufficient, which meant a return to the classic pallet.

When we look back a few years, we see how natural our willingness to make continuous improvements has become: Not only for the success of the company, but also for a better ecological balance. And should this not be the case, we still have the choice to compensate for less than optimal measures for the environment or to do better in the next project. Our corporate guidelines remind us at this point of our mission and responsibility for future generations.