ISO 9001 - Our way to re-certification

Current topic

Quality standards put to the test

It's been another year since we prepared and passed the surveillance audit for ISO 9001. faco-metalltechnik.de/blog/iso-9001. A lot has happened in the meantime. Due to Corona and in view of the increasing steel and raw material costs, we had to cope with some changes and challenges. However, our quality awareness always came first.

Now it was time for the main event, the re-certification. It takes place every three years. You can imagine that there was a certain basic nervousness among us due to the importance of the deadline.

TÜV Saar visited us on site on two dates to determine how well our quality standards can withstand objective criteria throughout the company. A major difference from the one-day monitoring audit is the focus on all areas of the company and not just sub-areas. Key areas include administration, production, purchasing, sales and the executive level.

Consistent documentation

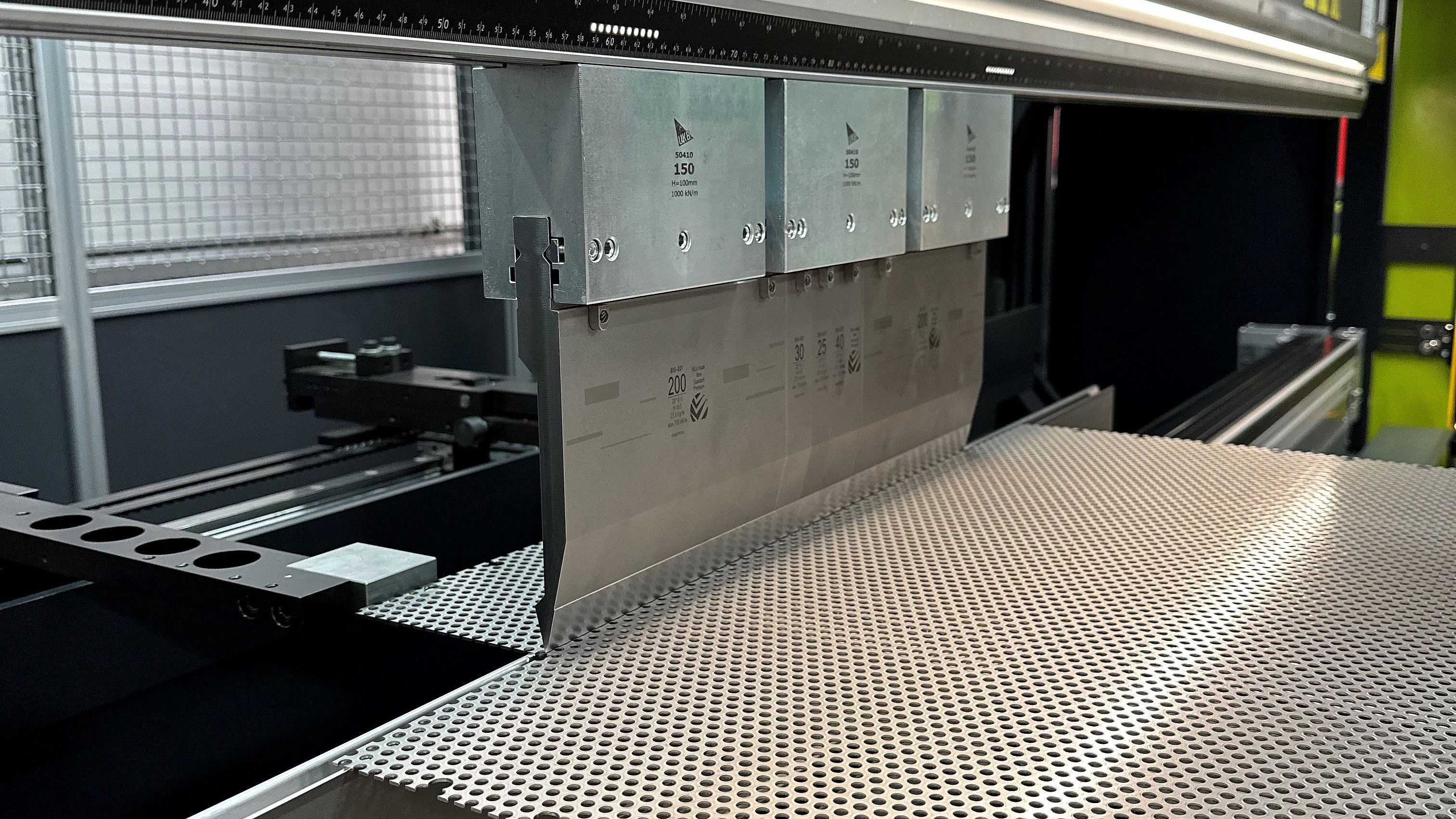

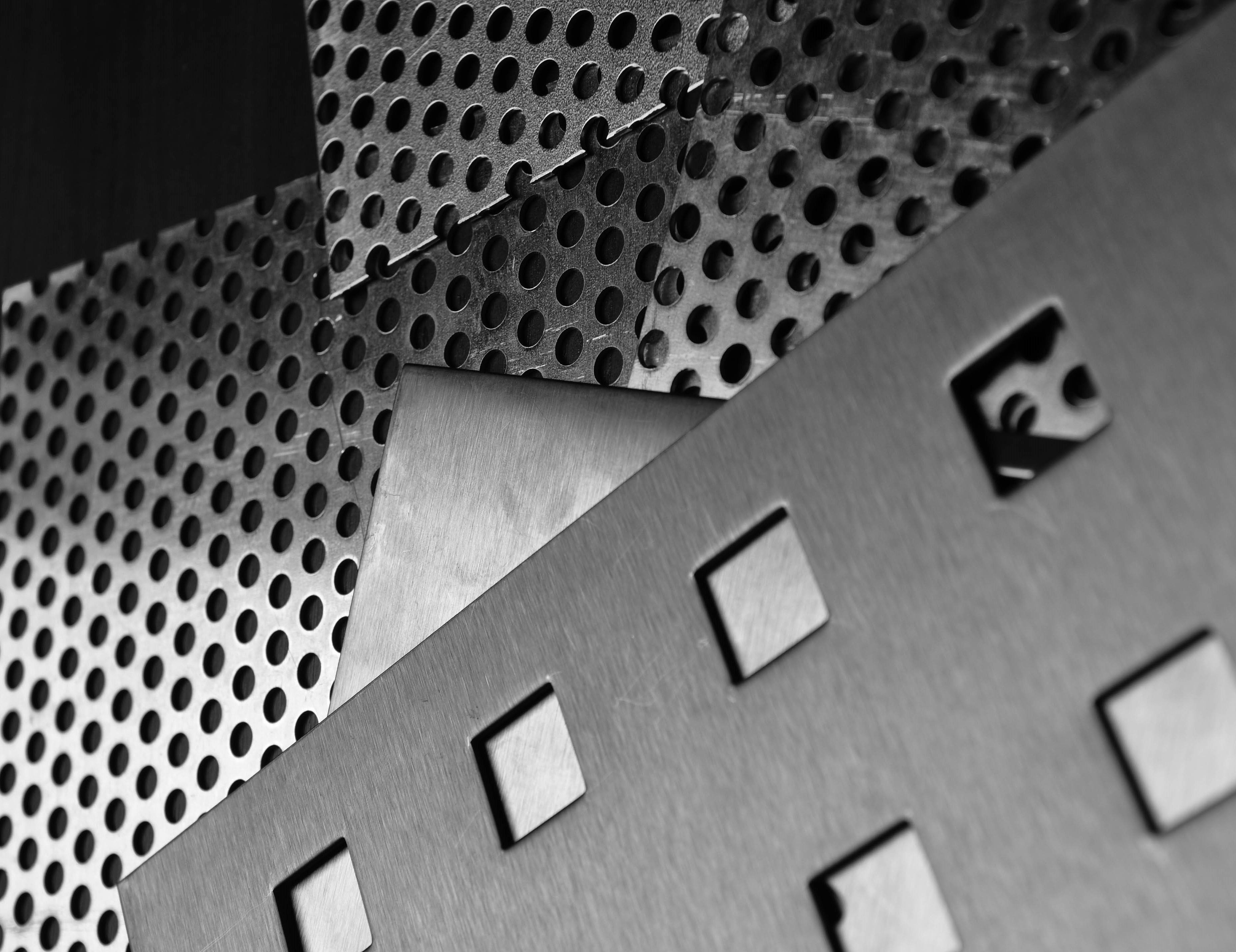

In the run-up to the audit, all processes in administration and production are documented regularly, systematically and in accordance with specific quality standards. The documentation serves as a guideline during an ISO quality audit and defines the target state. Comparing whether the actual processes in day-to-day operations look as they are documented is an essential part of the audit.

It is completely normal that people do not always repeat themselves 100% when working and that small deviations in the work processes occur. When differences are added up over a longer period of time, changes in the result eventually become visible. To ward off the beginnings, a guideline set in stone is therefore essential.

Occupational safety sets the standards

In the area of occupational safety, minor lapses can be detrimental to health. Inspection routines include, for example, the stability of ladders, the proper functioning of tools, and even the maintenance of production equipment, including checks on the electronic infrastructure. No plug goes unchecked. To ensure that every person in the company is informed about the importance of occupational safety and that our safety philosophy remains internalized, we train our team regularly. These trainings also fall under the ISO quality inspection.

Teamwork

The preparation for re-certification took a lot of time for our internal team of responsible persons. As for the previous audits, the management, the plant management and one other employee were involved. In addition, employees from the respective departments provide relevant documents.

On the days of the audit, everyone in the company realizes that things are getting serious. The auditor does not hide behind folders or Excel spreadsheets. If he notices inaccuracies in the documentation, he may well have a detailed discussion with the relevant employees. This was the experience of a new colleague in production. Since he had not used the welding fume extraction system, he had to answer for it. Fortunately, it had no negative impact on the evaluation. On 19.05.2022 we received the notification that we had passed the re-certification.

We are very happy about it, because the certificate clearly proves the quality of our performance and confirms us in our actions.

Quality management promotes crisis-proof corporate planning

The entire scope of an ISO certification can only be described in part in one article. In addition to the production- and administration-specific aspects and the process-oriented audit, overarching management qualities are also examined. Questions include:

How are we positioned when external unforeseen changes occur? How crisis-proof is our long-term planning? We will address this exciting topic in one of our next blog articles.